quấn ngang xung quanh máy dán nhãn ống

1. Apply to food, pharmaceutic, daily chemical, stationery, plastic industries etc.

2. Mainly used to automatically stick adhesive label on cylinder or small conical products which is unable to be carried vertically, such as tube, cylinder bottle, water injection, conical tube etc. High labeling precision, stable work ability, neat, no wrinkle, no bubble.

3. Suit for single or similar diameter products, orbit unadjustable and Can be matched with bottle feeder, ribbon printer, date printer, etc

Thông số kỹ thuật

| Kích thước ghi nhãn | (L) hơn 10 mm (W) 110-100mm | Cán bên trong đường kính | 76mm |

| Kích thước sản phẩm | (D) 10-16mm16-26mm 26-36mm (H) dưới 100mm | Đường kính cán ngoài | 350mm |

| Dán nhãn chính xác | + -1mm | Cung cấp năng lượng | AC220V 50Hz 3kW |

| Tốc độ ghi nhãn | 40-150 (chiếc / phút) (liên quan đến kích thước vật liệu và nhãn) | Kích thước máy | (L) 2000 * (W) 1700 * (H) 1500mm |

Chi tiết nhanh

Loại: Máy dán nhãn

Trạng thái: Còn mới

Ứng dụng: Đồ uống, Hóa chất, Hàng hóa, Thực phẩm, Máy móc & Phần cứng, Y tế

Loại bao bì: Chai

Chất liệu bao bì: Giấy, nhựa

Lớp tự động: Tự động

Loại điều khiển: Điện & Không khí

Điện áp: 110v / 220v

Công suất: 1.5KW

Nơi xuất xứ: Thượng Hải, Trung Quốc (Đại lục)

Tên thương hiệu: VKPAK

Kích thước (L * W * H): 2100 * 700 * 1000mm

Cân nặng: 300kg

Chứng nhận: GMP

Dịch vụ hậu mãi cung cấp: Kỹ sư có sẵn cho máy móc dịch vụ ở nước ngoài

Tên sản phẩm: quấn ngang xung quanh máy dán nhãn ống

Chức năng: Dán nhãn ống

Chất liệu: Thép không gỉ S304

Tốc độ ghi nhãn: 60-150 Chai / phút

Cách sử dụng: ghi nhãn ngang

Ưu điểm: Đội ngũ hỗ trợ chuyên nghiệp

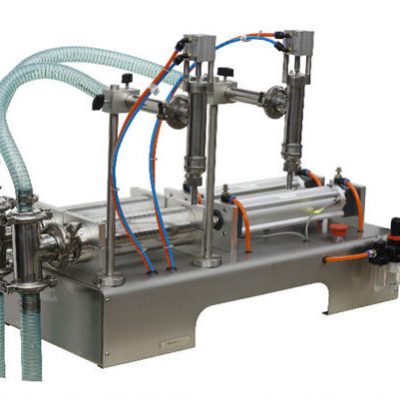

A horizontal wrap around tube labeling machine is a machine that is designed to wrap labels around cylindrical tubes with high efficiency and accuracy. This type of machine is ideal for labeling a wide range of products, including cosmetic tubes, toothpaste tubes, food containers, and other cylindrical products.

The machine is designed with a horizontal orientation, which enables it to handle large volumes of products in a compact and efficient manner. The labeling process starts with the product being fed into the machine, which then positions it in the correct position for labeling. The label is then applied to the product as it is rotating, ensuring a smooth and even application.

The machine is equipped with advanced features such as a touch screen control panel, which makes it easy to operate and adjust the settings. The control panel also provides real-time monitoring of the labeling process, enabling the operator to make any necessary adjustments to ensure consistent and accurate labeling.

The machine is also equipped with a high-speed labeling system, which can apply labels at speeds of up to 200 tubes per minute. This high speed capability ensures that the machine can keep up with the demands of a fast-paced production environment.

In addition, the machine is equipped with a built-in quality control system, which checks the accuracy of the labeling process and alerts the operator if any problems are detected. This ensures that the product is labeled with the correct information and meets all quality standards.

The horizontal wrap around tube labeling machine is also designed to be easy to maintain, with removable and replaceable components that can be quickly and easily replaced if needed. This helps to minimize downtime and reduce the cost of maintenance.

In conclusion, a horizontal wrap around tube labeling machine is a versatile and efficient labeling solution for a wide range of products. With its advanced features, high speed capabilities, and easy maintenance, it is an ideal choice for companies looking to improve the accuracy and efficiency of their labeling process.